Materialqualität

Abrasionsstabilität und gute Polierbarkeit für langlebige Prothesenzähne.

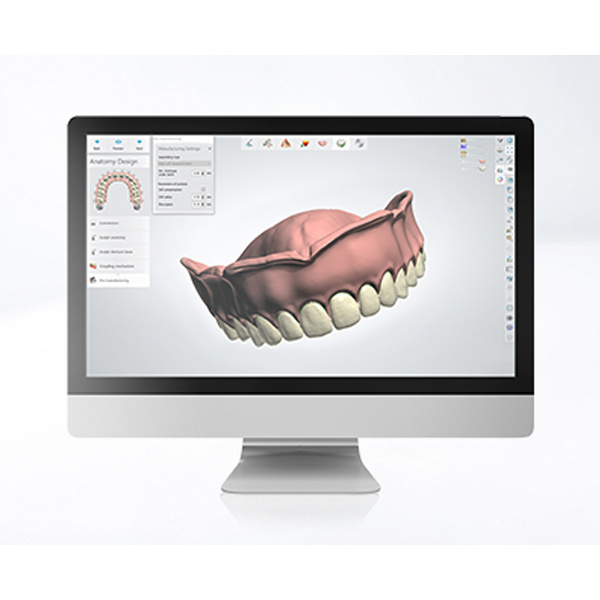

VITA VIONIC SOLUTIONS est un système de matériaux innovant et parfaitement adapté pour la fabrication fiable de prothèses amovibles numériques. Grâce à la flexibilité des combinaisons de matériaux pré-confectionnés, fraisés ou imprimés, vous pouvez adapter le flux de travail de manière optimale à vos besoins spécifiques. Le résultat va d’une grande esthétique à une rentabilité maximale ou à un mélange intelligent - toujours avec une qualité de matériau convaincante et la PERFECT MATCH par rapport à la gamme du teintier VITA.

Avec une grande sécurité de processus et une manipulation simple, VITA VIONIC SOLUTIONS offre ainsi une solution fiable et efficace pour la fabrication de prothèses amovibles numériques.

Abrasionsstabilität und gute Polierbarkeit für langlebige Prothesenzähne.

Integrierter Farbverlauf für mehr

Natürlichkeit.

Einfache, sichere Verarbeitung.

Kompatibel mit den gängigen

Fräs-Systemen.

Réalisez rapidement et à moindre coût des prothèses amovibles imprimées d’une qualité convacante.

Vous trouverez des informations plus détaillées dans la section suivante.

Réalisez des prothèses amovibles numériques esthétiques et à un coût optimisé en mélangeant des matériaux imprimés et fraisés.

Vous trouverez des informations plus détaillées dans la section suivante.

Réalisez des prothèses amovibles numériques sans faire de compromis sur l’esthétique naturelle, la qualité et la résistance à l’abrasion.

Vous trouverez des informations plus détaillées dans la section suivante.

Votre niveau économique (Flux de travail d’impression)

Votre niveau économique (Flux de travail d’impression)

Utilisez la nouvelle technologie d'impression et réalisez des prothèses à moindre coût.

• Efficace en termes de coûts et de temps

• Compatibilité chromatique optimale avec le teintier VITA

• Des restaurations imprimées de qualité VITA

Vous trouverez ici la brochure des produits.

Économiques

Fabrication rapide et économique de prothèses immédiates, de prothèses de remplacement, de prothèses amovibles définitives ainsi que de couronnes/bridges transitoires grâce à l'impression 3D.

Efficacité

Fabrication fiable et reproductible de plusieurs prothèses amovibles en une seule fois. Accélération de la production et de l'assurance qualité grâce à des processus automatisés et validés et aux propriétés des matériaux.

Sécurité du processus

Profitez des matériaux parfaitement adaptés les uns aux autres, dans la qualité bien connue de VITA. Faites confiance à un fournisseur unique pour des flux de travail sécurisés, combinés à des imprimantes et des unités de post-polymérisation validées.

| 1. Procédé CAO |

Flexibilité

Aide au montage numérique de prothèses amovibles partielles et complètes grâce à sept concepts pour toutes les classes d'occlusion. Réalisable aussi bien avec la dent artificielle VITA VIONIC VIGO qu'avec des restaurations fraisées ou imprimées.

Simple

Les propositions initiales prédéfinies minimisent la nécessité de retouches manuelles.

Rapide

Les prothèses peuvent être fabriquées rapidement et facilement à l'aide de nombreux systèmes de fraisage ouverts et d'impression 3D courants.

|

2. Impression d’essayage

|

Économique

Création rapide, économique en matériaux et en coûts de prothèses d’essayage fonctionnelles pour les prothèses amovibles partielles et complètes.

Facile à usiner

Vérification sans effort de l’adaptation, de la fonction, de l’occlusion et de la phonétique ainsi que bonne aptitude au polissage. Individualisation simple pour l’essayage esthétique possible.

Sans odeur et durable

Résine à faible odeur qui se distingue des autres produits du marché (Ø DLC 2 ans) par sa longue durée de conservation de 3 ans.

|

3. Impression de la base prothétique

|

Résistante

Les patients bénéficient de prothèses durables grâce à la haute résistance aux chocs du matériau, qui réduit le risque de rupture sous la charge. Une faible adhérence de la plaque dentaire contribue au confort de port.

Équilibré

Le profil équilibré des propriétés mécaniques est convaincant en ce qui concerne le travail à la rupture, la résistance à la flexion et le module d'élasticité.

Excellente aptitude à l'usinage

Des temps d'impression courts, une faible rétraction et donc une grande précision d'ajustage sont autant d'arguments convaincants que la bonne aptitude au polissage.

Vous trouverez ici de plus amples informations.

| 4. Impression des dents artificielles |

Esthétique

Disponible en neuf couleurs naturelles et résistantes avec Perfect Match par rapport au teintier VITA, qui répondent de manière fiable à des exigences élevées grâce à leur bonne aptitude au polissage.

Résistance

Les faibles valeurs d'usure confirment la qualité des restaurations stables et résistantes à l'abrasion.

Polyvalent

Convient aux dents artificielles permanentes ainsi qu'aux restaurations temporaires par couronnes et bridges et peut donc être utilisé de manière polyvalente en prothèse amovible partielle et complète.

Vous trouverez ici de plus amples informations.

| 5. Fixation des éléments dentaires dans la base |

Contrôle de l'adaptation

Vérifier le positionnement correct des dents prothétiques imprimées dans les cavités de la base prothétique imprimée à l'état de base (lavées mais non ré-exposées).

Collage simple

Appliquer la résine liquide de base prothétique dans les cavités à l'aide d'un petit pinceau ou d'une seringue.

Post-exposition

L'assemblage des deux éléments à l'état de base se fait par exposition dans un appareil validé.

| 6. Personnalisation |

Précision

La combinaison équilibrée de stabilité et de fluidité rend le modelage précis facile et efficace.

Naturel

Reconstitution gingivale d'aspect naturel grâce à une gamme de couleurs sélectionnées du matériau gingival.

Résistance

Le matériau convainc par sa grande capacité de charge et sa résistance à la surface.

Fiabilité

Reproduction fidèle au naturel des facettes colorées de la denture naturelle grâce à divers effets colorés brillants et à un traitement intuitif.

Simple

Modification de la couleur d'une grande simplicité d'un seul coup de pinceau grâce aux couleurs chromatiques pour le contrôle systématique de la chromaticité et esthétique optimale de la gencive.

Efficacité

Traitement efficace grâce à des effets de couleur ponctuels ou des couleurs appliquées en surface de manière très efficace avec des viscosités idéalement assorties.

Votre niveau compétence (Flux de travail mixte : usinage et impression)

Votre niveau compétence (Flux de travail mixte : usinage et impression)

Profitez de la flexibilité de VITA VIONIC SOLUTIONS et mélangez des éléments fraisés avec des éléments imprimés.

• Production rentable de prothèses d'essayage et de bases prothétiques imprimées

• Une grande esthétique et une qualité convaincante des éléments dentaires

• Pour une utilisation optimale de vos imprimantes et fraiseuses

Vous trouverez ici la brochure des produits.

Fabrication à coûts optimisés

Le mélange de traitement intelligent entre l'impression et le fraisage avec les matériaux VITA VIONIC garantit une fabrication rapide et optimisée en termes de coûts.

Esthétique de qualité

Vous trouverez la VITA PERFECT MATCH pour une esthétique enthousiasmante dans la dent artificelles VITA VIONIC VIGO préconfectionnée tout comme dans les dents fraisées dans VITA VIONIC DENT DISC multiColor.

Qualité fiable

Tous les matériaux répondent à des normes de qualité élevées et convainquent par leurs propriétés matérielles optimales.

| 1. Procédé CAO |

Flexibilité

Aide au montage numérique de prothèses amovibles partielles et complètes grâce à sept concepts pour toutes les classes d'occlusion. Réalisable aussi bien avec la dent artificielle VITA VIONIC VIGO qu'avec des restaurations fraisées ou imprimées.

Simple

Les propositions initiales prédéfinies minimisent la nécessité de retouches manuelles.

Rapide

Les prothèses peuvent être fabriquées rapidement et facilement à l'aide de nombreux systèmes de fraisage ouverts et d'impression 3D courants.

|

2. Impression d'essayage

|

Économique

Création rapide, économique en matériaux et en coûts de prothèses d'essayage fonctionnelles pour les prothèses amovibles partielles et complètes.

Facile à usiner

Vérification sans effort de l'adaptation, de la fonction, de l'occlusion et de la phonétique ainsi que bonne aptitude au polissage. Individualisation simple pour l'essayage esthétique possible.

Sans odeur et durable

Résine à faible odeur qui se distingue des autres produits du marché (Ø DLC 2 ans) par sa longue durée de conservation de 3 ans.

|

3. Impression de la base prothétique

|

Résistante

Les patients bénéficient de prothèses durables grâce à la haute résistance aux chocs du matériau, qui réduit le risque de rupture sous la charge. Une faible adhérence de la plaque dentaire contribue au confort de port.

Équilibré

Le profil équilibré des propriétés mécaniques est convaincant en ce qui concerne le travail à la rupture, la résistance à la flexion et le module d'élasticité.

Excellente aptitude à l'usinage

Des temps d'impression courts, une faible rétraction et donc une grande précision d'ajustage sont autant d'arguments convaincants que la bonne aptitude au polissage.

Vous trouverez ici de plus amples informations.

| 4. Réalisation des éléments dentaires ou Préparation des dents artificielles |

Qualité du matériau

Résistance à l'abrasion pour des dents artificielles durables.

Esthétique

Dégradé de couleur intégré pour un aspect plus naturel. Obtenir rapidement un résultat convaincant grâce à une bonne aptitude au polissage.

Souplesse

Mise en oeuvre simple et sûre. Compatible avec tous les systèmes de fraisage les plus courants.

Esthétique

Translucidité, fluorescence et opalescence sont combinées dans la dent artificielle VITA VIONIC VIGO stratifiée en trois dimensions pour une esthétique convaincante.

Qualité du matériau

Les propriétés mécaniques du matériau de la dent caractérisent VITA VIONIC VIGO comme une dent VITA Premium.

Sécurité de processus

Grâce à la conception de la dent optimisée pour le flux de travail numérique, VITA VIONIC VIGO contribue à un gain de temps et d'efficacité.

| 5. Fixation des dents à la base |

Liaison sûre

Le système auto-durcissant à 2 composants assure une liaison sûre.

Fixation précise

Une faible épaisseur de film dans la cavité permet une fixation précise et sans interstice.

Simple et rapide

Un travail rapide et propre pour une liaison sûre.

| 6. Personnalisation |

Précision

La combinaison équilibrée de stabilité et de fluidité rend le modelage précis facile et efficace.

Naturel

Reconstitution gingivale d'aspect naturel grâce à une gamme de couleurs sélectionnées du matériau gingival.

Résistance

Le matériau convainc par sa grande capacité de charge et sa résistance à la surface.

Fiabilité

Reproduction fidèle au naturel des facettes colorées de la denture naturelle grâce à divers effets colorés brillants et à un traitement intuitif.

Simple

Modification de la couleur d'une grande simplicité d'un seul coup de pinceau grâce aux couleurs chromatiques pour le contrôle systématique de la chromaticité et esthétique optimale de la gencive.

Efficacité

Traitement efficace grâce à des effets de couleur ponctuels ou des couleurs appliquées en surface de manière très efficace avec des viscosités idéalement assorties.

Votre niveau économique (Flux de travail d’impression)

Votre niveau économique (Flux de travail d’impression)

Réalisez des prothèses numériques sans compromis sur l'esthétique naturelle, la qualité et la stabilité à l'abrasion.

• Qualité convaincante de tous les matériaux du flux de travail

• Esthétique et fonctionnalité maximales

• Possibilités flexibles pour les prothèses amovibles partielles ou complètes

Vous trouverez ici la brochure des produits.

Esthétique proche de la nature

Grâce à des éléments dentaires esthétiquement convaincants et des couleurs gingivales naturelles pour les bases prothétiques.

Qualité du matériau exceptionnelle

Qualité VITA reconnue avec des propriétés fonctionnelles exceptionnelles.

Possibilités flexibles

Les matériaux VITA VIONIC conviennent pour les prothèses amovibles complètes ainsi que partielles telles que prothèses à châssis métallique et travail combiné.

| 1. Procédé CAO |

Flexibilité

Aide au montage numérique de prothèses amovibles partielles et complètes grâce à sept concepts pour toutes les classes d'occlusion. Réalisable aussi bien avec la dent artificielle VITA VIONIC VIGO qu'avec des restaurations fraisées ou imprimées.

Simple

Les propositions initiales prédéfinies minimisent la nécessité de retouches manuelles.

Rapide

Les prothèses peuvent être fabriquées rapidement et facilement à l'aide de nombreux systèmes de fraisage ouverts et d'impression 3D courants.

|

2. Fraisage d’une prothèse d’essayage

|

Confortable

Essayage en cire confortable grâce à la fabrication de prothèses CFAO grand format en cire blanche.

Précision

Montage précis grâce à des logements minutieusement fraisés à partir de la construction numérique.

Simple

Possibilité de correction simple puisque le montage peut être modifié lors de l'essayage.

|

3. Fraiser la base prothétique définitive

|

Stable

Le matériau résistant aux chocs assure une grande stabilité. Cela favorise positivement la durée de vie de la base prothétique.

Précision

Le matériau peut être fraisé avec précision dans la machine FAO, ce qui permet d'obtenir une excellente adaptation à la crête, sans rétraction de polymérisation.

Esthétique rose

Disponible dans les 4 couleurs de gencives : classic pink, classic pink translucent, soft pink et dark pink.

| 4. Préparation des dents artificielles ou Réalisation des éléments dentaires |

Esthétique

Translucidité, fluorescence et opalescence sont combinées dans la dent artificielle VITA VIONIC VIGO stratifiée en trois dimensions pour une esthétique convaincante.

Qualité du matériau

Les propriétés mécaniques du matériau de la dent caractérisent VITA VIONIC VIGO comme une dent VITA Premium.

Sécurité de processus

Grâce à la conception de la dent optimisée pour le flux de travail numérique, VITA VIONIC VIGO contribue à un gain de temps et d'efficacité.

Qualité du matériau

Résistance à l'abrasion pour des dents artificielles durables.

Esthétique

Dégradé de couleur intégré pour un aspect plus naturel. Obtenir rapidement un résultat convaincant grâce à une bonne aptitude au polissage.

Souplesse

Mise en oeuvre simple et sûre. Compatible avec tous les systèmes de fraisage les plus courants.

| 5. Fixation des dents à la base |

Liaison sûre

Le système auto-durcissant à 2 composants assure une liaison sûre.

Fixation précise

Une faible épaisseur de film dans la cavité permet une fixation précise et sans interstice.

Simple et rapide

Un travail rapide et propre pour une liaison sûre.

| 6. Personnalisation |

Précision

La combinaison équilibrée de stabilité et de fluidité rend le modelage précis facile et efficace.

Naturel

Reconstitution gingivale d'aspect naturel grâce à une gamme de couleurs sélectionnées du matériau gingival.

Résistance

Le matériau convainc par sa grande capacité de charge et sa résistance à la surface.

Fiabilité

Reproduction fidèle au naturel des facettes colorées de la denture naturelle grâce à divers effets colorés brillants et à un traitement intuitif.

Simple

Modification de la couleur d'une grande simplicité d'un seul coup de pinceau grâce aux couleurs chromatiques pour le contrôle systématique de la chromaticité et esthétique optimale de la gencive.

Efficacité

Traitement efficace grâce à des effets de couleur ponctuels ou des couleurs appliquées en surface de manière très efficace avec des viscosités idéalement assorties.

VITA VIONIC® DIGITAL VIGO

Flexibel

Für herausnehmbare Total- und Teilprothetik sowie gefräste und gedruckte Arbeiten.

Größte Auswahl

7 Prothetikkonzepte inkl. Kreuzbiss, alle Bissklassen.

Effizient

Eine Datenbank für alle Aufstellkonzepte - kein Wechsel zwischen verschiedenen Zahnlinien. Leichte Auswahl geeigneter Formen durch multifunktionales Zahndesign.

VITA VIONIC® TRY-IN RESIN

Kostengünstig

Schnelle, materialsparende und kosteneffiziente Erstellung von Funktionseinproben für Total- & Teilprothetik

Leicht zu bearbeiten

Mühelose Überprüfung von Passung, Funktion, Okklusion und Phonetik. Gut polierbar. Einfache Individualisierung für Ästhetikeinprobe möglich.

Geruchsarm und haltbar

Geruchsarmes Harz das sich durch seine lange Haltbarkeit von 3 Jahren von den Marktbegleitern (Ø MHD 2 Jahre) abhebt.

VITA VIONIC® BASE RESIN IMPACT

Materialqualität

Abrasionsstabil für langlebige Prothesenzähne.

Ästhetik

Integrierter Farbverlauf für mehr Natürlichkeit. Schnell zum überzeugenden Ergebnis dank guter Polierbarkeit.

Flexibilität

Einfache, sichere Verarbeitung. Kompatibel mit allen gängigen Fräs-Systemen.

Erreichen Sie das nächste Qualitätslevel beim 3D-Druck mit dem schlagzähen Druckmaterial für herausnehmbare Prothesenbasen VITA VIONIC® BASE RESIN IMPACT.

Die hervorragende Schlagzähigkeit des Produktes reduziert die Bruchgefahr unter Belastung.

Neben der Brucharbeit sorgen hohe Biegefestigkeit und optimierte E-Modul-Werte für ein ausbalanciertes Eigenschaftsprofil und bilden damit Basis für die langlebige Prothesenversorgung.

Lorem ipsum dolor amet aesthetic photo booth activated charcoal occupy iPhone schlitz squid. Everyday carry 3 wolf moon raw denim semiotics pok pok tattooed readymade bushwick. Humblebrag skateboard green juice mixtape polaroid ethical, messenger bag pitchfork sriracha hammock. Fam twee 3 wolf moon, authentic woke stumptown bespoke.

Norbert Wichnalek, HIGHFIELD.DESIGN, Augsbourg, Allemagne

Marc Wagenseil, VITA conférencier international, Edmonton AB, Canada

Lukas Wichnalek et Arbnor Saraci, HIGHFIELD DESIGN, Augsbourg, Allemagne

Équipe Wichnalek, HIGHFIELD DESIGN, Augsbourg, Allemagne

Eelco van Wort, Dental Design Centrum, Pays-Bas

Urban Christen, Hunzenschwil, Suisse

Das Indikationsspektrum geht weit über die klassische Vollprothese hinaus. Es ist auch möglich, herausnehmbare Versorgungen auf Mini-Implantaten herzustellen. Mehr noch – auch die klassische Klammerprothese kann einfach und schnell gefertigt werden.

Laden Sie sich jetzt kostenfrei den DENTAL VISIONIST mit den drei spanenden Fallberichten runter und erfahren Sie mehr über die vielfältigen Einsatzmöglichkeiten!

_V02.jpg)

Wie aus der polychromatischen VITA VIONIC DENT DISC multiColor heute passgenaue Premiumzähne im digitalen Workflow entstehen und welche Vorteile daraus resultieren, zeigen im Folgenden Norbert Wichnalek, Lukas Wichnalek, Patricia Strimb und Arbnor Saraci (alle Zahntechnik Wichnalek – HIGHFIELD.DESIGN, Augsburg, Deutschland).

Marc Wagenseil zeigt in diesem Fallbericht, wie traditionelle Erfahrung und neue Technologie bei komplexen Implantatfällen erfolgreich zusammenwirken.

.png)

Die multichromatische Ronde aus der bewährten VITA MRP (Microfiller Reinforced Polymermatrix) Kompositrezeptur bietet für Kombinationsprothetik jetzt die gewohnte Qualität und Ästhetik von VITA Premiumzähnen, die patientengerecht und passgenau in der Konstruktionssoftware entstehen. Im folgenden Interview berichten Lukas Wichnalek und Arbnor Saraci (beide Zahntechnik Wichnalek – HIGHFIELD DESIGN, Augsburg, Deutschland), wie sie die Ronde erfolgreich einsetzen.

VITA Zahnfabrik H. Rauter GmbH & Co. KG

Spitalgasse 3

79713 Bad Säckingen

Germany

Phone: +49 7761 562 0

Hotline: +49 7761 562-222

E-Mail: info@vita-zahnfabrik.com

© 2025 VITA Zahnfabrik. All rights reserved.