Backed by science – quality you can trust

VITA PHYSIODENS performance is not only based on decades of experience with dentures, but is also backed by science. On this page, you will find selected studies, internal investigations and independent tests that demonstrate key properties such as abrasion resistance, color fastness, material behavior and functionality.

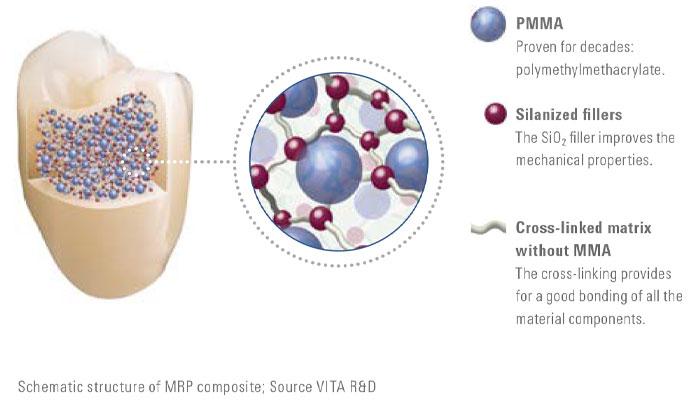

VITA PHYSIODENS is developed and manufactured entirely in Germany – with the latest technology and the highest precision and devotion to detail. The basis for the exceptional quality is the proven MRP composite (microfiller reinforced polymer matrix), which was specially developed for denture requirements.

Scientifically proven material advantages:

- High abrasion resistance: The highly cross-linked polymer matrix with homogeneously distributed, polymerized silicon dioxide fillers ensures a particularly resistant surface – ideal for long-term use.

-

Safe grinding: The material can be processed precisely without losing stability or esthetics.

-

Innovative post-pressing method: the three layers – enamel, dentine and neck – polymerize evenly and tightly. The results: : no cracking, no chipping, no flaking.

These technological properties make VITA PHYSIODENS a reliable choice for challenging denture restorations.

Overview of material properties

Physical properties:

| Flexural strength | 80 MPa |

| Modulus of elasticity | 4.350 MPa |

| Vickers hardness HV 0,5/30 | 275 MPa |

| Water absorption | 26,1 μg/mm3 |

| Solubility in water | 1,2 μg/mm3 |

Chemical composition:

| Components | Percentage by weight |

| PMMA | 84 – 86 |

| Silicon dioxide | 14 – 15 |

| Pigments | < 1 |

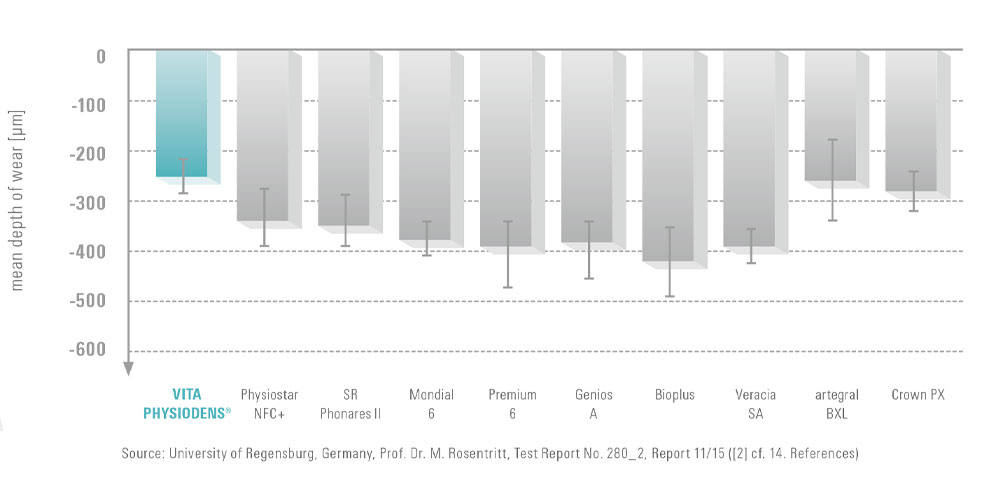

The clinical longevity of prosthetic teeth depends largely on their abrasion behavior. In an independent study conducted by the University of Regensburg, the wear behavior of various tooth lines was tested under realistic conditions – with convincing results for VITA PHYSIODENS.

Materials and methods

In the “pin-on-block wear test,” eight test specimens per brand were examined in a chewing simulator.

Test parameters

Steatite ball used as an antagonist

50 N load force

120,000 cycles at 1.2 Hz

830 thermal cycles at 5–55 °C

Measurement of the average depth of the wear mark

Results

VITA PHYSIODENS – made from the proven MRP composite, it showed the lowest average wear depth among all the tooth lines tested. This indicates particularly high abrasion resistance and load capacity in clinical use.

Conclusion

The study shows:

- Excellent wear resistance of VITA PHYSIODENS

- Reliable material performance even under thermal and mechanical stress

- MRP composite as a key technology for durable denture teeth

Source: University of Regensburg, Prof. M. Rosentritt, Test Report No. 280_2, Report 11/15

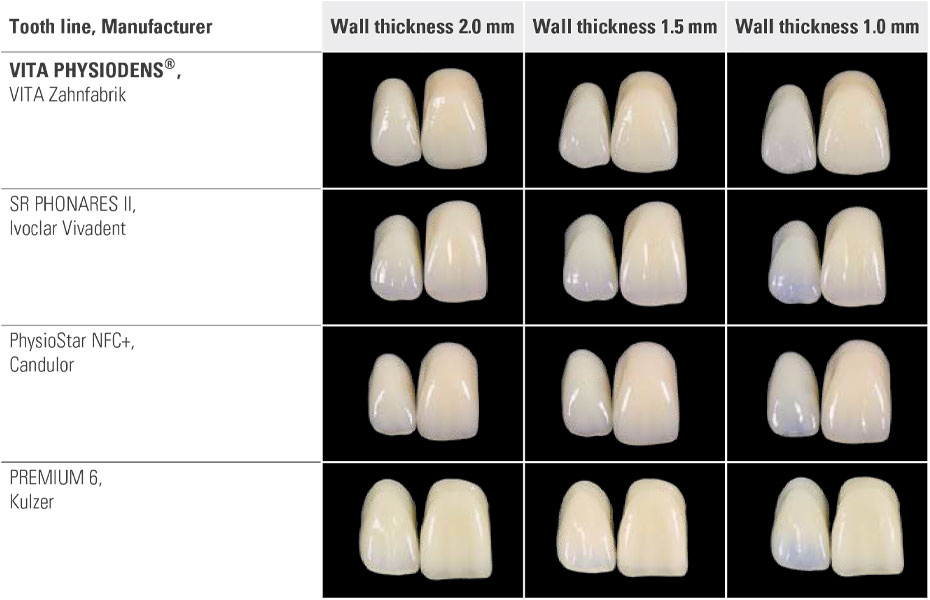

How shade-stable are denture teeth after grinding? This question was answered in an internal study conducted by VITA Zahnfabrik using various brands, with a focus on VITA PHYSIODENS.

Material and methods

Anterior tooth sets in shade A2 with comparable geometry were selected for the test. Tooth 12 was manually ground palatally using a cross-toothed carbide burr in three stages with wall thicknesses of 2.0 mm, 1.5 mm and 1.0 mm. After each step, a visual assessment of the shade stability was performed in comparison to the untreated tooth 11 of the same set. The results were documented using photographs

Results

As with all the materials tested, chromaticity decreased with reduced wall thickness - a known effect in polymer-based materials. However, VITA PHYSIODENS showed good shade stability in comparison, even with a reduced wall thickness.

Conclusion

The study confirms:

- VITA PHYSIODENS offers high color stability, even after grinding.

- Shade changes in thinner wall thicknesses are typical for this material.

- Tooth-colored denture plastics can compensate for the decreasing chromaticity.

Source: Internal study, Technical Service VITA Zahnfabrik, Report 06/17

How does long-term storage in staining media affect the shade stability of denture teeth? In a separate internal study, this question was examined by VITA Zahnfabrik using VITA PHYSIODENS prosthetic teeth made of MRP composite.

Materials and methods

To study shade stability, denture teeth made of VITA PHYSIODENS (MRP composite) were stored in three typical staining media over a period of six months: tea, coffee and red wine. The media were kept at a constant temperature of 20°C and stirred regularly to simulate realistic conditions. At set intervals, the teeth were removed, cleaned under running water with a toothbrush, and then stored again. After six months, a final cleaning was performed and a visual comparison with a reference sample was conducted.

Results

The visual comparison between the stored samples and the reference sample showed no discernible changes in the shade. The denture teeth made of VITA PHYSIODENS exhibited excellent shade stability even after six months in staining media.

Conclusion

The internal study confirms the high shade stability of VITA PHYSIODENS denture teeth made of MRP composite. Even after prolonged exposure to tea, coffee and red wine, no discoloration was detected. This underscores the suitability of the material for esthetically demanding and long-lasting restorations.

Source: Internal study, VITA Research & Development, Report 07/17

VITA Zahnfabrik H. Rauter GmbH & Co. KG

Spitalgasse 3

79713 Bad Säckingen

Germany

Phone: +49 7761 562 0

Hotline: +49 7761 562-222

E-Mail: info@vita-zahnfabrik.com

© 2026 VITA Zahnfabrik. All rights reserved.